Views: 0 Author: Site Editor Publish Time: 2025-07-07 Origin: Site

The best wire brush for you depends on what you need to clean. Use a steel brush for tough jobs. It is good for cleaning metal or taking off rust and paint. Brass wire brushes are better for softer metals. They are also good for delicate things like jewelry or electrical parts. Nylon wire brushes are gentle. They help clean plastic and painted things without harm. Anhui Wanze Brush Industry Co., Ltd. makes many types of custom wire brushes. They have roller brushes, disc brushes, and more for any cleaning job. Picking the right brush stops damage and gives you the best results.

Pick steel wire brushes for hard cleaning jobs. They work well to take off rust and paint from strong metals and concrete. Do not use them on soft or painted surfaces. This helps stop scratches and sparks.

Use brass wire brushes for gentle cleaning jobs. They are good for soft metals, jewelry, and electrical parts. Brass brushes do not make sparks. They help keep delicate surfaces safe.

Choose nylon wire brushes for safe and smooth cleaning. They work well on wood, plastic, and painted surfaces. Nylon brushes can handle chemicals and heat. They also help stop scratches.

Always pick the right brush for your material and job. This keeps your things safe and helps you clean better.

Follow safety tips like wearing gloves and goggles. Use light pressure and check brushes for damage. This keeps you and your tools safe.

Steel wire brushes are used for strong cleaning jobs. The bristles are made from steel, like carbon steel or stainless steel. These brushes come in many shapes, such as cup, wheel, and roller brushes. Each shape is good for a different job. Twisted wire brushes are best for hard cleaning. Crimped wire brushes are better for lighter work. Anhui Wanze Brush Industry Co., Ltd. makes custom steel wire brushes for many uses. They help with metal cleaning, woodworking, and making things in factories.

Steel wire brushes are strong and last a long time. The steel bristles are tough and do not break easily. They can handle hard cleaning over and over. Stainless steel wire brushes do not rust, so they are good for wet places. Carbon steel wire brushes are best for dry cleaning jobs. The table below lists the materials used in steel wire brushes and what they are good for:

Material Type | Description | Typical Uses and Properties |

|---|---|---|

High Tensile Oil Tempered High Carbon Steel | Aggressive wire, 0.008”–0.035” diameter | Cylinder brushes, weld prep, paint and corrosion removal |

Hard Drawn High Carbon Steel Wire | Fine wire, 0.003”–0.006” diameter | Light deposit removal, polishing |

Low Carbon Mild Steel | Medium tensile, high ductility, 0.003”–0.006” | Polishing, light scrubbing, some corrosion resistance |

Brass Plated Steel | Hard-drawn, 0.008”–0.028” diameter | Corrosion resistance, utility power brushes |

Galvanized Steel Cable | Hard drawn, various sizes | Long wearing, aggressive power and strip brushes |

Steel wire brushes clean very well. They remove rust, paint, and dirt from metal fast. These brushes last a long time because they are strong. You can use them for many jobs, like getting metal ready for welding or cleaning concrete. But steel wire brushes can scratch soft things. Do not use them on painted or soft surfaces. They can also make sparks, so be careful. Always wear gloves and eye protection when you use a steel brush.

Tip: Use stainless steel wire brushes outside or in wet places to stop rust.

Steel wire brushes are best for hard cleaning jobs. They work well for taking off rust, paint, and dirt from metal tools, machines, and concrete. Many jobs use steel wire brushes, like building, fixing cars, and making metal parts. You can also use them to smooth metal edges and get things ready for painting or welding. Anhui Wanze Brush Industry Co., Ltd. can make steel wire brushes, roller brushes, and strip brushes just for you. Their skill helps you get the right tool for every cleaning job.

Brass wire brushes have soft bristles made of brass. They clean things without scratching them. These brushes come in many shapes, like hand brushes and roller brushes. The bristles are about 0.006 inches thick. They are put in rows to clean evenly. Handles are made from plastic or strong wood. This makes them easy to hold and use. Brass wire brushes are good for cleaning soft metals and small parts. They work well when you do not want to hurt the surface.

Tip: Brass wire brushes are great for cleaning rust off battery ends, jewelry, and electrical parts.

Property Type | Details |

|---|---|

Physical Properties | Wire sizes go from 0.004" to 0.0204". You can get crimped or straight brass wires. |

Chemical Properties | Brass wire brushes do not make sparks or attract magnets. |

Application Context | They are safe for cleaning machine parts in risky places. |

Additional Notes | Brass does not rust easily and cleans gently. |

Brass wire brushes do not make sparks, so they are safe near fire. The soft bristles bend and fit into small spaces. You can clean grooves and tight spots without scratching.

Pros:

Brass wire brushes are softer than steel wire brushes. They clean gentle surfaces without harm.

They do not rust, so you can use them in wet places.

They do not make sparks or attract magnets. This makes them safe for electric and risky jobs.

They are good for taking off rust, cleaning electric parts, and shining jewelry.

Cons:

Brass wire brushes are not as strong as steel. They do not work well for tough rust or hard paint.

You must be careful with thin brass surfaces to stop damage.

Use brass wire brushes when you need to clean gently. They are perfect for taking rust off battery ends and cleaning electric parts. They also shine jewelry. You can use them on musical tools, wood, and food machines. Brass wire brushes help take off paint from soft things and clean small cracks. Many jobs, like fixing cars, boats, and woodwork, use brass wire brushes for safe cleaning.

Anhui Wanze Brush Industry Co., Ltd. makes special brass wire brushes for all these jobs. You can ask for roller brushes, strip brushes, or other kinds for your needs. Their skill helps you pick the best brush for every job and surface.

Nylon wire brushes have soft nylon bristles for gentle cleaning. You can find them as hand brushes, roller brushes, or strip brushes. These brushes use different types of nylon, like Nylon 6, Nylon 66, and Nylon 610. Each nylon type gives the brush a special strength and bendiness. Handles can be made from wood, plastic, or metal. This makes them easy to hold and use. The bristles stay in place with staple set, twist-in wire, or strip brush assembly. Nylon abrasive brushes work for both light and tough cleaning jobs. Anhui Wanze Brush Industry Co., Ltd. makes custom nylon wire brushes for any job you need.

Nylon 6, 66, 610, 612, 11, and 12 filaments

Handles: wood, plastic, composite, stainless steel, aluminum

Construction: staple set, twist-in wire, strip brush assembly

Nylon abrasive brushes are flexible and resist chemicals. You can use them with many cleaners and solvents. The bristles bend to fit any shape, so you get a smooth finish. These brushes last a long time and do not wear out fast. They can handle heat up to 350°F. Different nylon types let you pick how much water or heat the brush can take. Even with rough use, nylon abrasive brushes stay flexible.

Property | Description |

|---|---|

Flexibility | Nylon filaments bend and recover, fitting any surface for a smooth finish. |

Chemical Resistance | Withstand many chemicals, oils, and solvents, so you can use them for tough cleaning. |

Abrasion Resistance | Excellent resistance to wear, keeping the brush effective for many uses. |

Strength & Durability | High tensile strength, so the brush lasts through repeated cleaning. |

Water Absorption | Nylon softens with water, making it even more gentle on surfaces. |

Temperature Resistance | Handles high heat, so you can use it in many environments. |

UV Resistance | Moderate resistance to sunlight, but best used indoors or away from direct sun. |

Nylon abrasive brushes are softer than metal wire brushes. They clean gently and do not scratch delicate things. These brushes do not make sparks, so they are safe near fire. They give a smooth finish on wood, plastic, and painted surfaces. You can use them for cleaning, polishing, or putting on paint. But nylon abrasive brushes are not as strong as steel. They do not remove heavy rust or thick paint well. The bristles might fray if you use them on very rough jobs.

Feature | Nylon Abrasive Brushes | Metal Wire Brushes |

|---|---|---|

Cleaning Approach | Gentle cleaning, less abrasive | Aggressive cleaning, best for tough deposits |

Surface Damage Risk | Low risk of scratching delicate surfaces | High risk of scratching soft surfaces |

Finish Quality | Smooth, even finish | Rougher, textured finish |

Durability | Long-lasting, self-sharpening | Durable, but bristles may bend or break |

Safety | No sparks, safe for flammable areas | Sparks can occur, safety risk in some settings |

Applications | Woodworking, electronics, food industry | Metal fabrication, welding, industrial cleaning |

Cost | Good value for light duty, long life | Wide price range, effective for heavy-duty jobs |

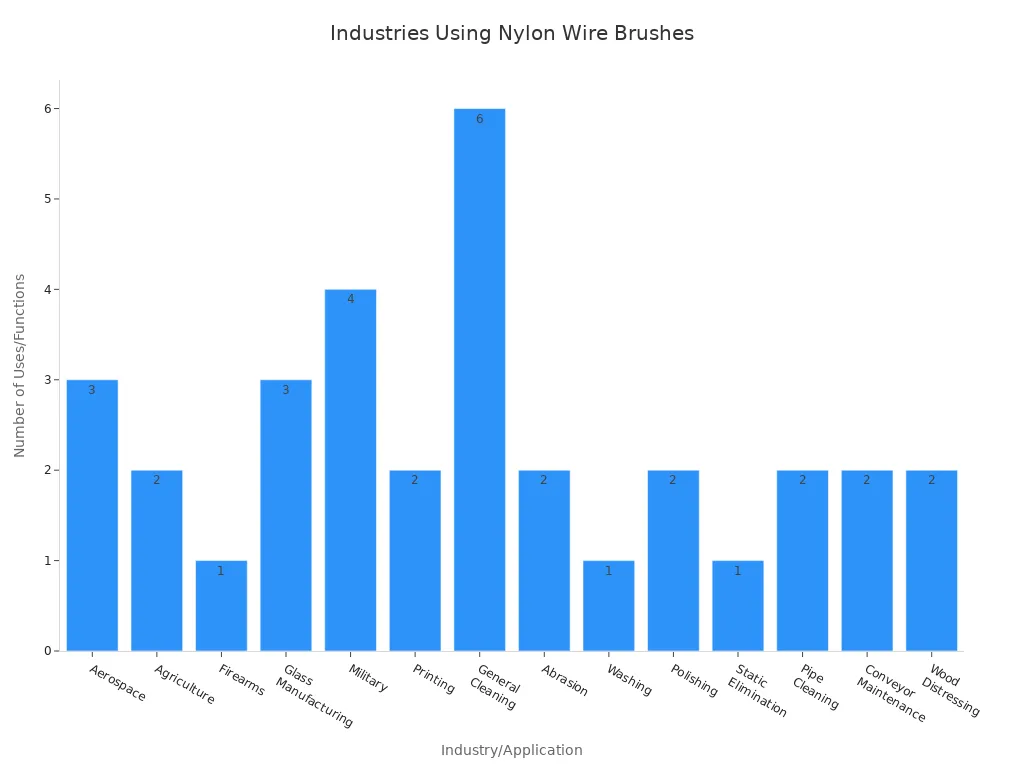

Nylon abrasive brushes are good for many cleaning jobs. They work best on wood, plastic, and painted things where you do not want scratches. These brushes remove paint, rust, and weld spatter. You can use them for polishing, finishing, and cleaning at home or in factories. They also help with static and pipe cleaning. Many industries use nylon abrasive brushes, like aerospace, farming, printing, and glass making. Anhui Wanze Brush Industry Co., Ltd. can make roller brushes, strip brushes, and other nylon wire brushes just for you.

Tip: Pick nylon abrasive brushes when you want a smooth finish and safe cleaning for any surface.

Picking the right wire brushes helps you clean better. Each brush works best for certain jobs and materials. You need to match the brush to what you are cleaning. This stops damage and gives a good finish.

Here is a simple guide to help you choose the right brush for your job:

Brush Type | Best Applications | Suitable Materials | Cleaning Effectiveness | Surface Finish & Safety Considerations |

|---|---|---|---|---|

Steel wire brushes | Rust removal, paint stripping, weld prep, heavy-duty cleaning | Hard metals (steel, iron), concrete | Removes rust and paint fast | Can scratch soft surfaces; produces sparks; aggressive |

Brass wire brushes | Cleaning electrical parts, polishing, gentle rust removal | Softer metals (aluminum, brass), electronics, jewelry | Gentle cleaning, no sparks | Protects delicate surfaces; wears faster |

Nylon abrasive brushes | Cleaning plastic, wood, fiberglass, painted surfaces, food equipment | Wood, plastic, fiberglass, soft metals | Light rust and paint removal | Smooth finish; safe for all surfaces; no sparks |

Tip: Use steel wire brushes for hard cleaning on tough metals. Pick brass wire brushes to keep soft metals safe. Nylon abrasive brushes are best for gentle cleaning on delicate things.

You can also use roller brushes or strip brushes for big jobs. Anhui Wanze Brush Industry Co., Ltd. makes custom brushes for any cleaning job you have.

Think about the surface before you start cleaning. The wrong wire brushes can scratch or damage it. Here is how each brush works on different surfaces:

Wire Brush Type | Surface Suitability | Performance and Applications |

|---|---|---|

Steel wire brushes | Best for ferrous metals, concrete, stone | Aggressive cleaning and surface preparation; removes rust and paint quickly; not for soft metals or plastics |

Brass wire brushes | Softer metals, electronics, cast iron | Gentle cleaning and surface prep; avoids scratches; safe for electrical work; wears faster |

Nylon abrasive brushes | Wood, plastic, aluminum, painted surfaces | Non-sparking; gentle cleaning; ideal for irregular shapes; gives a smooth finish; safe for all surfaces |

Steel wire brushes clean hard surfaces fast. Do not use them on soft metals or plastic. They can scratch or ruin the finish.

Brass wire brushes are safe for soft metals and electronics. They do not make sparks, so they are safe near fire.

Nylon abrasive brushes are good for wood, plastic, and painted things. They do not scratch or hurt the finish. Use them for gentle cleaning and prep.

Note: Always use light pressure with wire brushes. This keeps the wires straight and the surface smooth.

For big areas or special shapes, use roller brushes or strip brushes. Anhui Wanze Brush Industry Co., Ltd. can make these brushes just for your job.

Think about the environment when you pick a brush. Steel and brass wire brushes can be recycled, but recycling uses energy. Nylon abrasive brushes are made from plastic and do not break down, but some places can recycle them.

When you use the right wire brushes, you protect your things and get a good finish. This saves you time and money. For special jobs, ask Anhui Wanze Brush Industry Co., Ltd. for custom brushes or other tools.

Picking the right brush helps you clean well and keeps your things safe. You must match the brush to your material, job, and how you want it to look. Use this easy checklist to help you choose:

Identify the Material

Find out what you need to clean. Is it steel, aluminum, brass, wood, plastic, or painted?

Steel wire brushes are best for hard metals and concrete.

Brass wire brushes work for soft metals and electric parts.

Nylon brushes are gentle for wood, plastic, and painted things.

Define the Task

Decide if you need to remove rust, polish, or clean gently.

Tough jobs need steel wire brushes.

Gentle cleaning or polishing needs brass or nylon brushes.

Consider the Desired Surface Finish

Think about if you want the surface rough or smooth.

Steel wire brushes make the surface rough for painting.

Nylon brushes make it smooth and even.

Select the Brush Type and Size

Pick hand brushes, roller brushes, strip brushes, or disc brushes.

Roller brushes clean big areas fast.

Strip brushes clean edges and small spaces.

Check Brush Construction

Look at how thick the wires are and how they are twisted.

Thick wires take off more but can scratch.

Thin wires clean and polish gently.

Review Common Mistakes

Avoid these mistakes to keep your tools and surfaces safe:

Common Mistake | Explanation | Consequences |

|---|---|---|

Picking the wrong brush | Using one brush for every job | Bad results, brush wears out fast |

Wrong brush material | Using carbon steel on stainless steel | Mixing metals, damage |

Not matching brush to job | Using any brush for any task | Poor cleaning, safety problems |

Too much pressure | Pushing too hard | Wires break, can be dangerous |

Ignoring brush details | Not checking wire size or type | Bad cleaning, safety risks |

Factor in Cost and Maintenance

Hand wire brushes cost less and are simple to use.

Change old brushes to keep cleaning strong.

Keep brushes dry so they do not rust or get ruined.

Tip: Always pick a brush that fits your material and cleaning goal. This keeps your things safe and gives a better finish.

Using wire brushes the right way keeps you and your tools safe. Follow these safety and care tips every time you clean:

Wear goggles and gloves to keep your eyes and hands safe from flying wires.

Use the right brush for your job. Steel wire brushes can make sparks, so do not use them near fire.

Do not push too hard or go too fast. Let the brush do the work. Too much force can break wires and hurt you.

Check your brush before you use it. Look for bent or broken wires. Change broken brushes right away.

Store brushes in a cool, dry place. Keep steel brushes away from water so they do not rust.

Clean brushes after using them. Take out dirt and dry them well. For nylon brushes, let them air dry to stop mold.

Keep different brushes apart. This stops mixing and keeps each brush working well.

Use nylon brushes for electric or fire risk places. They do not carry electricity or make sparks.

Pick brass brushes for soft surfaces or electric parts. They clean gently and do not spark.

Note: Taking care of your wire brushes makes them last longer and keeps cleaning safe and easy.

If you need special roller brushes, strip brushes, or other cleaning tools, Anhui Wanze Brush Industry Co., Ltd. has many choices. Their team can help you find the best brush for any cleaning job.

There are lots of wire brushes to pick from. Each kind works best for certain jobs. Some are strong, and some are gentle. The table below shows what each brush does well and where to use it:

Brush Type | Strengths | Best Uses |

|---|---|---|

Steel | Very strong, lasts a long time | Cleaning tough messes, getting rid of rust |

Brass | Soft, does not make sparks | Cleaning soft metals, jewelry, electric parts |

Nylon | Smooth, safe with chemicals | Cleaning wood, plastic, or gentle surfaces |

Pick the brush that matches your job and what you are cleaning. Anhui Wanze Brush Industry Co., Ltd. can make special brushes for any job. They have many kinds, like strip brushes and round brushes. Look at all their products to find the best one for your cleaning or polishing work.

You should use a steel brush for heavy rust on hard metals. For light rust on soft metals, pick a brass wire brush. Anhui Wanze Brush Industry Co., Ltd. offers custom roller brushes for large surfaces.

Yes, you can use a nylon wire brush on painted surfaces. Nylon bristles clean gently and protect the finish. This makes them perfect for cleaning wood, plastic, or painted items without scratching.

Choose a strip brush for cleaning edges or narrow spaces. Pick a roller brush for cleaning large, flat areas quickly. Both types are available from Anhui Wanze Brush Industry Co., Ltd. and can be customized for your project.

Yes, brass wire brushes do not spark and do not attract magnets. You can safely use them for cleaning battery terminals, electrical contacts, and other sensitive parts.

You can order custom wire brushes, including steel, brass, and nylon types, from Anhui Wanze Brush Industry Co., Ltd. Visit their website to explore roller brushes, strip brushes, and other industrial brush solutions.

A strip brush is a versatile tool used in a variety of applications, including cleaning, sealing, and even as part of industrial machinery. Whether you're using it for a DIY project or for professional purposes, cutting a strip brush to the desired length or shape can seem challenging.

When it comes to brushes, there’s a wide variety of types and applications across different industries. Two types that are often confused are the strip brush and the regular brush.

IntroductionIn industries where cleanliness, precision, and efficiency are essential, tools like strip brushes play an important role. These specialized brushes have become indispensable in various applications, offering unique benefits that standard brushes cannot match.

In harsh industrial settings, the smallest component can make the biggest difference.

A clean production line is essential for consistent quality — yet dust and airborne particles often find ways to contaminate even the most controlled environments.

Static discharge ruins boards — but prevention is simpler than many realize. In electronics and PCB manufacturing, managing electrostatic discharge (ESD) is critical to product reliability.

Brass bristles deliver gentle abrasion and non-sparking performance — features that make brass stripping brush solutions a preferred choice for precise industrial applications.

Choosing the wrong industrial strip brushes can lead to unnecessary downtime, material damage, and inefficient sealing or cleaning performance.

The best paint brush depends on what you need. Natural and synthetic bristles have different strengths. Many artists pick synthetic brushes for latex or water-based paints. Natural bristles are good for oil-based products or stains. Synthetic brushes are easy to clean and make smooth edges. Natural brushes can make different textures and hold more paint. You should think about how well the brush works, how much it costs, how long it lasts, and how you want to use it, even for big jobs.

In the realm of painting, whether for professional or personal projects, the quality of your tools can significantly impact the outcome. Among these tools, the paint brush stands as a pivotal element. Understanding how to discern a good quality paint brush from a mediocre one is crucial for achieving the desired finish and efficiency in painting tasks. This article delves into the characteristics that define a high-quality paint brush, supported by research, expert opinions, and practical insights.

If you want a smooth finish, pick a good paint brush with the right bristles. The type of bristle is important. Natural bristles are best for oil-based paints. Synthetic bristles work well for water-based paints. Good brushes help you paint smoother and make neat lines. At Anhui Wanze Brush Industry Co., Ltd., you can get a special paintbrush made for careful work and high quality. These brushes are great for home projects and for professional use.

When you ask, "What type of paint brushes are best?" you might expect one simple answer. The truth is, the best paint brush depends on your painting projects, the type of paint you use, and your own experience. Picking the right paintbrush makes your work look better and helps you paint with less effort. You should think about the paint medium, the shape of the brush, the bristle material, and whether you are just starting out or have painted before.

When it comes to wall painting, the choice of tools can significantly impact the final outcome. Among these tools, the paint brush stands out as a fundamental instrument. Selecting the right type of brush is crucial for achieving a smooth, even finish and ensuring that the paint adheres properly to the surface. This article delves into the various types of paint brushes available for wall painting, examining their characteristics, advantages, and best use cases. By understanding these factors, both amateur and professional painters can make informed decisions that enhance their painting projects.

Quick answer for busy painters: Wipe excess color on a rag, rinse the bristles in lukewarm water (for acrylics) or a small amount of odorless mineral spirits (for oils), lather with brush soap or a gentle paint brush cleaner, rinse until clear, reshape the tip, and dry flat or bristles‑down. Avoid hot water, long soaks, and smashing the bristles against the cup.

The best Cylinder Brush material depends on your surface, debris load, and environment. Use nylon or PBT for cleaning delicate surfaces, abrasive nylon for controlled deburring, and stainless/carbon for heavy rust or scale. Pick trim and density for stiffness, and choose helical or chevron fills to manage debris and heat at line speed.

To clean an acrylic Paint Brush fast and safely: wipe excess paint on a rag, rinse in lukewarm water, lather with brush soap or gentle paint brush cleaner, rinse until clear, reshape the tip, and dry flat or bristles-down. Avoid hot water and harsh solvents that can warp bristles and loosen glue.

A Cylinder Brush is a rotating roller brush used for continuous, wide‑area cleaning, finishing, or deburring. To choose the right one, match filament (nylon, wire, PP/PBT), fill pattern (straight, helical, chevron), size (OD, face width), and line settings (tip speed, pressure) to your surface, debris, and speed.

A cylinder brush—also called a cylindrical brush or roller brush—is a rotating brush built around a shaft or core that keeps steady, wide‑area contact with a surface. With the right filament (cylinder brush hair), fill pattern, and speed/pressure settings, it can clean, deburr, polish, guide, or control moisture across continuous production lines with uniform, repeatable results.

The best wire brush for you depends on what you need to clean. Use a steel brush for tough jobs. It is good for cleaning metal or taking off rust and paint. Brass wire brushes are better for softer metals. They are also good for delicate things like jewelry or electrical parts. Nylon wire brushes are gentle. They help clean plastic and painted things without harm. Anhui Wanze Brush Industry Co., Ltd. makes many types of custom wire brushes. They have roller brushes, disc brushes, and more for any cleaning job. Picking the right brush stops damage and gives you the best results.

A wire brush has many strong filaments. These filaments scrub, polish, or get a surface ready. People use a wire brush to clean things. It helps remove rust or old paint. Many industries use different types of wire brushes. Some types are crimped end brushes, nylon micro twisted brushes, and scratch brushes. Each type works best for a certain job or material. Safety is important when using wire brushes. You should use them the right way. This is true for strip brushes or roller brushes. Trusted suppliers like Anhui Wanze Brush Industry Co., Ltd. make these brushes.